Company Profile

Main business areas: industrial field, municipal field, new energy materials

Professional provision of advanced environmental protection technology equipment, system integration, and overall solutions to environmental issues, including research and development design, equipment integration, engineering contracting, facility operation, etc

The first ecological protection and environmental governance industry science and technology innovation board listed enterprise in China. Stock abbreviation: Wandes, stock code: 688178

Desalination Technology

The water containing crude oil generated during the oil field extraction process, also known as produced water or oily wastewater. It is an important water source for oilfield reuse. The main sources are as follows:

※ Oil production wastewater: The bottom water of various crude oil storage tanks in the crude oil gathering and transportation dehydration station. The water temperature is high, the salinity is high, it is often alkaline, the dissolved oxygen is low, it contains saprophytic bacteria and Sulfate-reducing bacteria, the content of oil and organic matter is high, and it contains certain demulsifier components.

※ Well flushing wastewater: Regular well flushing for oil production downhole operations and water injection wells. It mainly contains pollutants such as petroleum, surfactants, and acids and alkalis.

※ Drilling sewage and mainline flushing water: sewage generated during the drilling process or sewage from regularly flushing the ground water injection mainline. Mainly containing petroleum, drilling fluid additives, rock cuttings, etc.

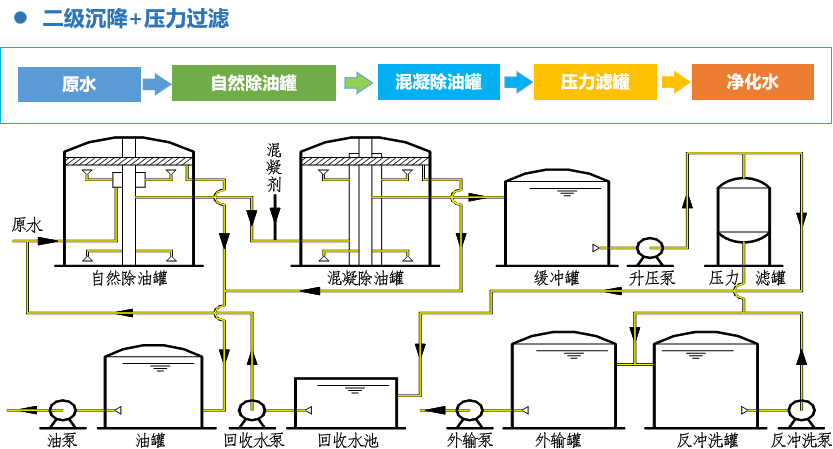

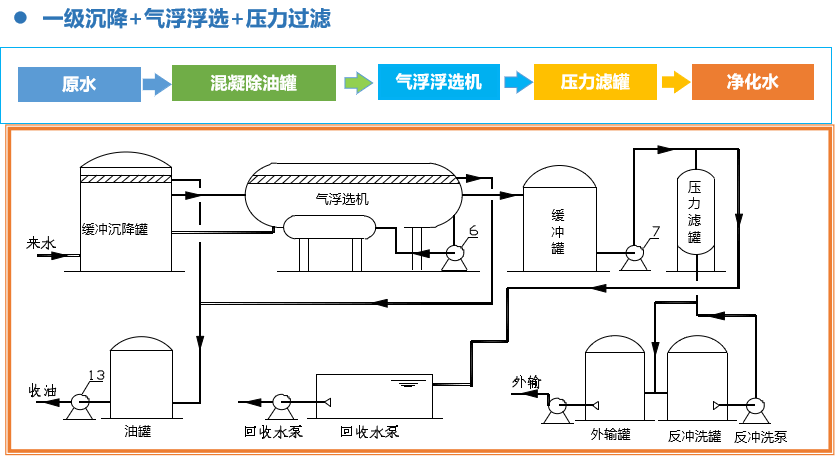

According to research, in the case of oilfield produced water being treated as oil recovery and reinjection water, the mainstream treatment technologies currently used in domestic oilfield produced water treatment systems include gravity oil removal tank, coagulation oil removal tank, air flotation oil removal equipment, coarse granulation tank, lateral coalescence oil removal device, and pressure filter tank. Membrane filtration technology is also required for reinjection water in ultra-low permeability layers. If the produced water needs to meet the discharge standards after treatment, further biological treatment and advanced treatment are needed to meet the discharge requirements.

Wandes has accumulated rich technical experience and project cases in the field of industrial wastewater treatment, including oil removal, SS removal, efficient biological treatment, and advanced oxidation. At present, Wandes' new energy materials business sector is carrying out lithium extraction from oilfield produced water. In order to ensure the quality of lithium materials produced at the end, there are extremely high requirements for the pre-treatment of oilfield produced water.

Case show